Industrial IoT with ESP8266 Node MCU with MAX6675 K-type Thermocouple Sensor with cloud platform Blynk App and Thingspeak App

Thermocouples are extensively used in various Industries some of which are listed below:

- In food and beverage industry pasteurisation, refrigeration, fermentation, brewing, and bottling.

- It offers accurate temperature readings for frying and cooking to ensure your food is well cooked.

- Restaurant appliances like grills, toasters, fryers, warmers, and ovens often use thermocouples.

- In the form of temperature-sensing probes in cooking equipment used in large-scale food processing operations.

- Also used in breweries because beer production requires precise temperatures for proper fermentation and prevention of microbial contamination.

Accurate temperature measurement for molten metals like steel, zinc, and aluminum can be challenging because of the extremely high temperatures involved. The temperature sensors widely used for molten metals are Types B, S, and R platinum thermocouples and Type K and N base metal thermocouples.

Manufacturing plastic products needs precise temperature control. Thermocouples are usually required in various areas for temperature monitoring during plastic processing. They’re used to measure the melting or surface temperature in diecasting moulds and injection.

- The furnace conditions will largely determine the appropriate thermocouple for high-temperature laboratory furnaces.

- The atmosphere where the thermocouple will be used, such as oxidising, reducing, or inert.

- The protective covering or sheath's temperature capability and Thermocouple wires' temperature capability.

- Thermocouples are indispensable components in melting furnaces, contributing to the efficiency and reliability of industrial processes.

- Extruders require high pressure and temperatures. Thermocouples for extruders are designed with a threaded adapter, which helps you position its sensor tip in molten plastic, usually under high pressure.

- You can get these thermocouples either in single or dual elements, incorporating a distinct threaded housing. Bayonet thermocouples (BT) and compression fitting (CF) thermocouples are commonly used on the parts of an extruder with low pressure.

Thermocouples in Melting Furnaces: Crucial Components for Temperature Monitoring

Melting furnaces play a pivotal role in various industrial processes, such as metal casting, glass manufacturing, and heat treatment. Maintaining precise temperature control is essential to ensure the quality and integrity of the final product. Thermocouples are fundamental components in these furnaces, providing accurate temperature measurements and enabling efficient temperature regulation.

Output voltage of thermocouple amplifier is directly proportional to the temperature of the furnace and is measured by a connected instrument, such as a temperature controller or a programmable logic controller (PLC).

Type K: Type K thermocouples are versatile and widely used in various industries. They cover a broad temperature range, from -270°C to 1,370°C, making them suitable for many melting furnace applications.

The primary role of thermocouples in melting furnaces is to provide accurate and real-time temperature measurements. This data is crucial for maintaining the desired melting temperature, ensuring product quality, and preventing overheating or underheating. Hence on periodic basis this data is uploaded to the cloud and made available to the users on mobile using different Apps.

Temperature controllers use thermocouple data to adjust heating elements, gas flow rates, or other control parameters to maintain a stable and precise melting temperature. This control process is essential for consistent product quality and energy efficiency. In case the temperature drops below a set value or increases beyond a set value immediately the notification will be sent to users through cloud.

Despite the above if no action is taken and abnormal temperature fluctuations continue, shutdown mechanisms will be triggered, minimizing potential risks and notifications will be sent to the users through cloud.

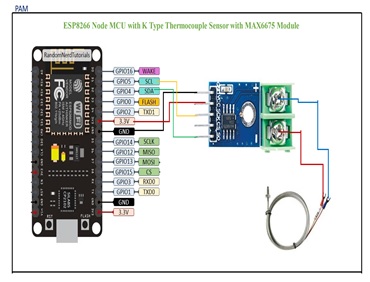

For connecting thermocouple to the cloud, we need to connect thermocouple to ESP8266 Node MCU using MAX6675 amplifier and provide internet connection to Node MCU to send the data to cloud. For this Node MCU must be coded and Apps must be installed both on Node MCU and mobile phones to which data needs to be sent.