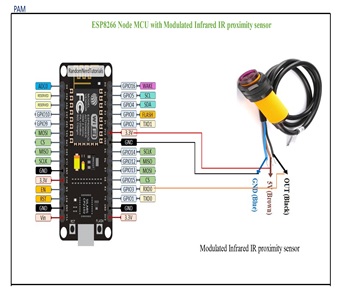

Industrial IoT using E18-D80NK Modulated Infrared IR proximity sensor as Item counter with

Node MCU for automated cloud system with Blynk App and Thingspeak App

Types of Infrared Proximity Sensors

Reflective Infrared Proximity Sensor

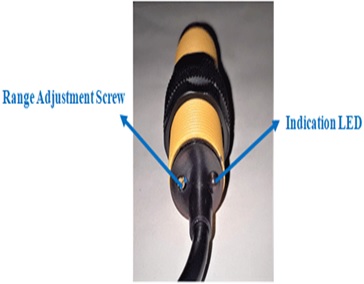

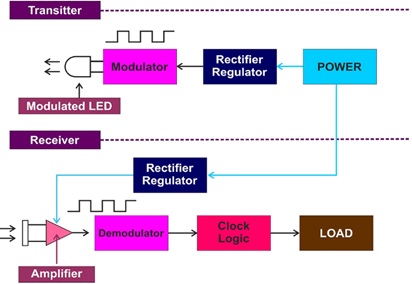

Modulated Infrared Proximity Sensor

Applications of Infrared Proximity Sensors

Robotics: Infrared proximity sensors are used in robotic systems for obstacle detection, collision avoidance, and object recognition. They help robots navigate complex environments and interact with objects safely.

Automation: In industrial automation, these sensors are used for object counting, conveyor belt control, and product positioning. They ensure accurate and efficient operation of automated systems.

Security: Infrared sensors can detect the presence of intruders or unauthorized access in security systems. They are commonly used in access control, surveillance, and alarm systems

Mobile Devices: Smartphones and other mobile devices often use infrared proximity sensors to detect the user’s proximity to the screen, adjusting display brightness and disabling touch input during calls

Advantages of Infrared Proximity Sensors

Non-contact sensing: Infrared sensors can detect objects without physical contact, reducing the risk of damage to both the sensor and the target object.

Wide detection range: Infrared sensors can detect objects at various distances, depending on the sensor’s specifications and design. This makes them suitable for a range of applications.

Resistance to environmental factors: Modulated infrared sensors, in particular, are less susceptible to interference from ambient light, dust, and moisture, providing reliable performance in various conditions.

Fast response time: Infrared sensors typically offer rapid response times, making them ideal for real-time applications and dynamic environments.

Compact size: Infrared proximity sensors are often compact, allowing for easy integration into devices and systems with space constraints.