Industrial IoT using Honeywell HIH-4000-003 Humidity sensor with

Node MCU for automated humidity system with Thingspeak App and push notifications on Blynk App

Honeywell HIH-4000-003 Sensor Introduction

Honeywell HIH-4000-003 Sensor Series Humidity Sensors are designed specifically for high volume OEM (Original Equipment Manufacturer) users. Direct input to a controller or other device is made possible by this sensor’s near linear voltage output. With a typical current draw of only 200 µA, the HIH-4000 Series is often ideally suited for low drain, battery operated systems. Tight sensor interchangeability reduces or eliminates OEM production calibration costs. Individual sensor calibration data is available.

HIH-4000 Series delivers instrumentation-quality RH (Relative Humidity) sensing performance in a competitively priced, solderable SIP (Single In-line Package). Available in two lead spacing configurations, the RH sensor is a laser trimmed, thermoset polymer capacitive sensing element with on-chip integrated signal conditioning. The sensing element’s multilayer construction provides excellent resistance to most application hazards such as dust, dirt, oils and common environmental chemicals.

Brand | Honeywell |

Model No. | HIH-4000-003 |

Accuracy | ±3.5% RH |

Voltage supply | 4 to 5.8 Vdc |

Current supply | 500 µA |

Operating temperature | -40 to 85 Deg.C |

Operating humidity | 0-100 % |

Storage temperature | -50 to 125 Deg.C |

Output Type | Analog Voltage |

Output | 3.198V @ 75.3%RH |

Mounting Type | Through Hole |

Features

- Molded thermoset plastic housing.

- Near linear voltage output vs % RH.

- Laser trimmed interchangeability.

- Low power design.

- Enhanced accuracy.

- Voltage output (1 st order curve fit)

- VOUT=(VSUPPLY)(0.0062(sensor RH) + 0.16), typical at 25 ºC

- Calculated values at 5 V

- Vout at 0% RH = 0.826 V

- Vout at 75.3% RH = 3.198 V

Potential Applications:

- Refrigeration equipment

- HVAC (Heating, Ventilation, and Air Conditioning) equipment

- Medical equipment

- Drying

- Metrology

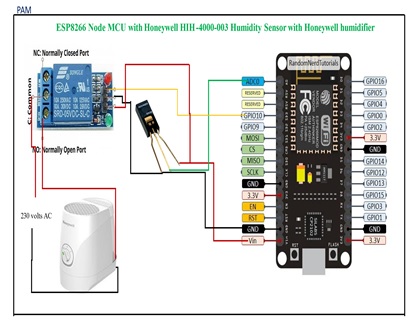

Computer Center Application: In computer centers maintaining humidity at 50% RH is extremely important to keep the servers healthy and give long life apart from maintaining temperature at 16 degree centigrade. Unfortunately the airconditioning system constantly removes the moisture from the server rooms and drains it off which is part of it’s function. This creates dry soldering on the soldered components of Servers which eventually fail. In data centers humidity is maintained at 50% RH due to use of very expensive Precision air conditioning units where as in computer Centers PACs are not affordable. Further the RH is not manually controllable hence we need to move to an automated system of Industrial IoT.

Advantages of automated system of Industrial IoT:

- We can set precise value of RH say 50%.

- As and when the RH drops below 50% the humidifier starts automatically and pumps water vapour into computer center.

- When the RH reaches 55% the humidifier switches off.

- Both time when the humidifier switches On and Off push notification will be sent to the registered mobile number.

- The RH value would be sent periodically toe the registered mobile the time interval to be decided by the user.

RH value is sent to cloud and then sent to user’s mobile at specific intervals using one of the cloud applications.