Inductive Proximity Sensor Interfaced with Arduino, Node MCU, ESP32 to count metal objects

Advantages:

- Without remote station or double head

- No recount if the can passes the sensor again after a reverse

- Can counting of up to 6,000 pieces/min.

- Can diameter 53 to 86 mm

- Outputs for 1/1, 1/2, 1/10 sockets

- Adjustable with teach-in function

- Aluminium and tinplate cans

- No second sensor is required

PLC Program for Counting Moving Objects on Conveyor

- This is a PLC Program to implement a program for counting objects on the moving conveyor.

- Table of Contents

- Counting Moving Objects on Conveyor

- Problem Diagram

- Problem Solution

- List of Inputs and Outputs

- PLC Ladder Logic for counting Objects on the conveyor

- Ladder Logic Explanation

- Result

- PLC Program to Count and Pack Boxe…

- Pause

- Unmute

- Loaded: 0.93%

- Remaining Time -28:33

- Captions

- Fullscreen

- Now Playing

- PLC Program to Count and Pack Boxes on Conveyors – Example Logics

- PLC Program to Count and Pack Boxes on Conveyors – Example Logics

- PLC Example – Schneider PLC Training | Eco Structure Machine Edition

- PLC Training 31 – Down Counter (CTD Instruction) | Counters in PLC Programming

- Object Size Detection using PLC Programming – Advanced PLC Course

- PLC Program to Control the Sequence of Conveyors – Online PLC Courses Free

- PLC Counter Instructions

- PLC Programming Counter Instruction

- Down Counter and Up-Down Counter in PLC | Free PLC Tutorial

- Example PLC Program for Boxes Counting and Buzzer

- PLC Program to Count and Pack Boxes on Conveyors – Example Logics

- Counting Moving Objects on Conveyor

- Objects are moving on the conveyor. We need to count the total number of objects collected at the end of conveyor and display it on the local control panel.

- Write a PLC program for this application.

Problem Solution

Here we use PLC ladder program to implement this logic.

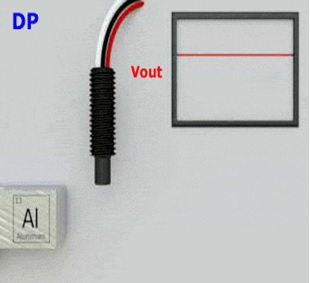

Mostly proximity sensors are used to detect the objects. Here we mount proximity sensor to detect the parts or objects moving on the conveyor.

Inductive sensor are mostly used to detect metal objects. For other type of objects, we use Capacitive proximity sensor for detecting the objects moving on the conveyor. We connect this sensor to the PLC and by using counter logic,we will count the number of objects and display the total number on the local control panel display.

Here we use UP counter for counting the collected Objects at the end of conveyor.

Note:- Here we considered simple application for counting objects. We considered proximity sensor for detecting the objects. Proximity sensor will sense the object and PLC UP counter will count the collected objects.

List of Inputs and Outputs

- Digital Inputs

- Start :- I0.0

- Stop :- I0.1

- Proximity :- I0.2 (Objects detection)

- Counter Reset PB :- I0.3

- Digital Output

- Cycle ON :- Q0.0

- M memory

- Counter Reset :- M0.1

- Total Objects collected :- MW10

- PLC Ladder Logic for counting Objects on the conveyor

- Ladder Logic Explanation

- For this application, we use S7-300 PLC and TIA portal software for programming. We can implement this logic by using other PLC also.

Network 1:

In first network we used latching circuit for cycle ON. Here we used START PB (I0.0 ) to start the cycle and STOP PB (I0.1) to stop the cycle.

Network 2:

PLC Counter instruction is used to count the number of objects. Proximity sensors are mounted near to the conveyor.

When an object comes near to the proximity sensor (I0.2), it will detect the object and output of the sensor becomes energize or changes to ON state.

When there will be no object near to the proximity sensor then output of sensor becomes de-energize or changes to OFF state.

PLC counter counts in the incremental way. Total counted Objects number will be stored in the memory word or register (MW10).

Note :- Above application may be different from actual application. This example is only for explanation purpose only. We can implement this logic in other PLC also. This is the simple concept of UP counter. By using this concept we can count objects moving on the conveyor or any other counting application. This logic is only part or for specific application logic only.

All parameters considered in example are for explanation purpose only, parameters may be different in actual applications.